- Current location:

- Home

- News

- Common problem

- New progress in high energy beam welding technology

New progress in high energy beam welding technology

The main areas of focus for current high-energy beam soldering are: 1 The large-scale of high-energy beam devices - large-scale power and large-scale processing of parts (and even parts integration). 2 The development of new equipment, such as pulse working mode and short-wavelength laser. 3 The intelligence of the equipment and the flexibility of processing. 4 beam quality improvement and diagnosis. 5 Study on the interaction mechanism of beam, workpiece and process medium. 6 beam composite. 7 welding of new materials. 8 extensions of the application area.

Latest developments in laser welding

1 new laser

(1) DC Slab CO2 laser,

(2) Diode-pumped YAG lasers,

(3) CO laser,

(4) Semiconductor lasers,

(5) Excimer lasers.

2 Large-scale laser power, pulse mode, and high-quality beam mode

Take the US PRC company as an example. A few years ago, the power of CO2 lasers used for cutting was mainly 1500~2000W, while the recent leading products were 4000~6000W. The thickness of 6000W cuttable stainless steel and carbon steel were 35mm and 40mm respectively.

3 Equipment intelligence and flexible processing

Especially for the YAG laser, it is extremely convenient to process due to the transmission of available optical fibers.

Its main features are: 1 multi-purpose machine. 2 Multi-station (up to 6) processing is possible with one laser machine. 3 fiber lengths up to 60m. 4 open control interface. 5 has a long-distance diagnostic function.

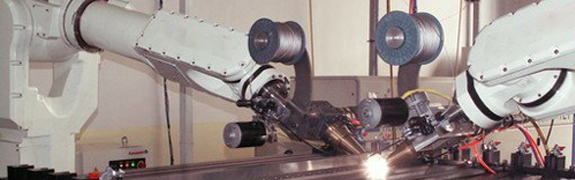

4 beam composite

The most important is laser-arc composite. During deep-fusion welding, plasma is generated above the molten pool. When combined processing, the plasma generated by the laser is beneficial to the stability of the arc; the combined processing can improve the processing efficiency; and the welding of materials with poor weldability such as aluminum alloy, duplex steel, etc. can be improved. Properties; can increase the stability and reliability of welding; usually, laser wire bonding is very sensitive, and it is easy and reliable to be combined with the arc.

Laser-arc composites are primarily lasers with TIG, Plasma and GMA. Through the mutual influence of laser and arc, each method's own deficiencies can be overcome, and a good composite effect is produced.

GMA has low cost and uses wire filling. It has strong applicability. The disadvantages are shallow penetration, low welding speed and high thermal load on the workpiece. Laser welding can form deep and narrow welds with high welding speed and low heat input, but the investment is high, the preparation precision of the workpiece is high, and the adaptability to aluminum and other materials is poor. The composite effect of Laser-GMA is manifested in the fact that the arc increases the bridging property of the gap for two reasons: one is to fill the welding wire, the other is to increase the arc heating range; the arc power determines the width of the top of the weld; the plasma generated by the laser is reduced. The arc is ignited and maintained to make the arc more stable; the laser power determines the depth of the weld;

From the energy point of view, the laser arc recombination has a significant improvement in welding efficiency. This is mainly based on two effects, one is that higher energy density leads to higher welding speed; the other is the superposition effect of two heat source interactions.

Comparison of GMA, laser wire and laser arc composite methods for welding line energy, weld section and energy utilization.

- Prev :Demand in the weldin

- Next :What are the wide-ra

- Share:

- Back to News List

Quick Navigation

Contact Us

- Add: Bridge over Yongkang City Economic Development Zone Boundary,Zhejiang Province

- Tel:0579-87441635

- E-mail:baoxingchina@163.com

- Mobile:15857973599

Follow Us